PRODUCTS CENTER

Ningjin APC Industries is a leading manufacturer specializing in development and production of Fire Protection Valves, Industrial Valves, and Marine Valves in North China.

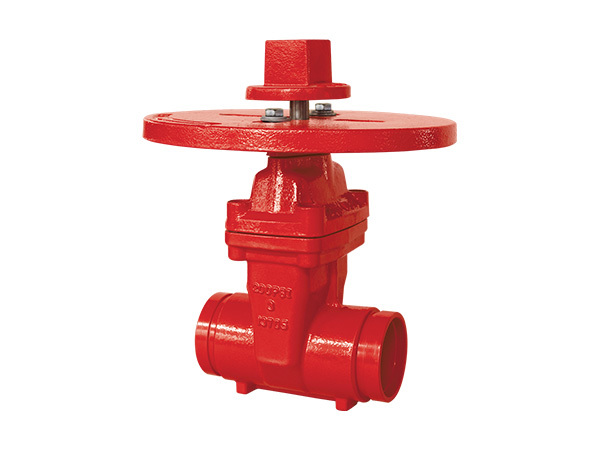

Resilient Wedge os&Y Gate Valve-Flangedx Grooved End

Learn More

300PSI NRS Flanged End Gate Valve Model: Z45-300

Learn More

一.Approval: FM approved UL/ULC listed

二.Usage: Before sprinkle head, before and after wet alarm valve and deluge valve, high-rising building fire fighting system, industrial factory building fire protection system.

三.Technical specification :

Pressure rating: 300psi

Temperature range : -20℃ to 120℃.

Structure:Butterfly type and groove end

Application : Indoor and outdoor usage

Double –seal disc : resilient EPDM coated

Factoroy Installed supervisiory tamper switch assembly

Design standard : API 609

Groove standard ANSI/AWWA C606

Top flange standard: ISO 5211

Test standard :FM 1112/UL 1091

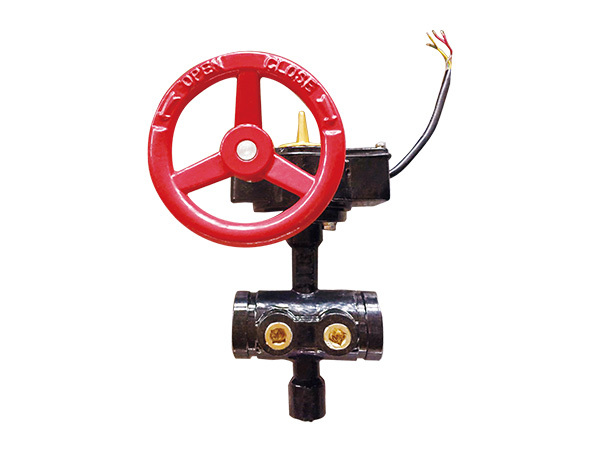

Model : GD-381X/GD-381Y

Learn More

一.Approval: UL/ULC listed

二.Usage: Before sprinkle head, before and after wet alarm valve and deluge valve, high-rising building fire fighting system, industrial factory building fire protection system.

三.Technical specification :

Fire protection grooved Butterfly Valve is UL/ULC listed with pressure rating 300psi or 175psi

Temperature range : -20℃ to 120℃.

Structure:Butterfly type and groove end

Application : Indoor and outdoor usage

Double –seal disc : resilient EPDM coated

Factoroy Installed supervisiory tamper switch assembly

Design standard : API 609

Groove standard ANSI/AWWA C606

Top flange standard: ISO 5211

Test standard: API 598

Model : HGD-381X / HGD-381X-175/HFGD-381X/HFGD-381X-175

Learn More

Gate Valve Model: Z85

Resilient Wedge NRS Gate Valve –Groove Ends

Technical Features

Conforms: ANSI / AWWA C515

Connections: Groove

Sizes: 2", 2½", 3", 4", 5", 6", 8", 10", 12"

Approvals: UL, ULC, FM, NSF/ ANSI 61 & NSF/ ANSI 372

2’’ only with FM

Maximum Working Pressure: 200 PSI (Maximum Testing Pressure: 400 PSI) conforms to UL 262, ULC/ORD C262-92, & FM class 1120/1130

Maximum Working Temperature: -20°C to 80°C

Groove standard : Metric or AWWA C606

Application: Buried underground connected with vertical indicator post and wall type indicator . Fire inflow water, drain pipe, high-rising building fire fighting system, industrial factory building fire protection system.

Coating Details: Epoxy coated interior and exterior by Electrostatic Spray conforms to AWWA C550

Disc: EPDM Rubber Encapsulated Ductile Iron Wedge

Gate valve can also be installed with handwheel

Certified lead-free by NSF/ ANSI 61 & NSF/ ANSI 372

Valve Material List

17

Countersunk Head Bolt

1

1045,ASTM A29

16

Platen

1

DI,ASTM A536 65-45-12

15

Coupling flange

2

DI,ASTM A536 65-45-12

14

Flat Washer

2

1045,ASTM A29

13

Nut

2

1045,ASTM A29

12

Stud

1

1045,ASTM A29

11

Bolt

1

1045,ASTM A29

10

Minipad

1

1045,ASTM A29

09

Wrench Nut

1

DI,ASTM A536 65-45-12

08

O-Ring

3

EPDM,ASTM D2000

07

Retainer Ring

1

C95400, ASTM B148

06

Cap

1

DI,ASTM A536 65-45-12

05

Stem

1

S.S.304,ASTM A276

04

Gasket

1

EPDM,ASTM D2000

03

Nut

1

C95400, ASTM B148

02

Disc

1

DI,ASTM A536 65-45-12 +EPDM,ASTM D2000

01

Body

1

DI,ASTM A536 65-45-12

NO.

Name

Qty

Material

Dimensions

3D Pictures

Advantages of APC Gate Valves

1.Wedge coated by high performance rubber through newest vulcanization technology to make sure precise dimension, good sealing and high corrosion resistance

2.Tight junction inner trim structure to assure longlife operation.

3.The bottom of gate valve adopted straight-through design, no foreigh matter store to make sure smooth flow and reliable sealing

4.Self-sealing design between the bonnect and body make the sealing more tight when pressure is higher wthin the allowable pressure range.

5. Multiple sealing structure to protect the stem under pessure during operation maintenance , no damage to the operator.

Learn More

Gate Valve Model: Z481

Resilient Wedge OS&Y Gate Valve – Flange ×Groove Ends

Technical Features

Conforms: ANSI / AWWA C515

Sizes: 2", 2½", 3", 4", 5", 6", 8", 10", 12"

Approvals: UL, ULC, FM, NSF/ ANSI 61 & NSF/ ANSI 372

Maximum Working Pressure: 200 PSI (Maximum Testing Pressure: 400 PSI) conforms to UL 262, ULC/ORD C262-92, & FM class 1120/1130

Maximum Working Temperature: -20°C to 80°C

Flange standard: ASME/ANSI B16.1 Class 125 or ASME /ANSI B16.42 Class 150 or BS EN1092-2 PN16 or GB/T9113.1

Groove standard : Metric or AWWA C606

Application: Indoor & Outdoor Use, Fire inflow water, drain pipe, high-rising building fire fighting system, industrial factory building fire protection system.

Coating Details: Epoxy coated interior and exterior by Electrostatic Spray conforms to AWWA C550

Disc: EPDM Rubber Encapsulated Ductile Iron Wedge

Mark: APC Gate valve can be installed with Tamper Switch

Certified lead-free by NSF/ ANSI 61 & NSF/ ANSI 372

Valve Material List

14

Cylinder Pin

1

S.S.304,ASTM A276

13

Countersunk Head Bolt

N

1045,ASTM A29

12

Lock Nut

1

1045,ASTM A29

11

Handwheel

1

1045,ASTM A29

10

Rotating Nut

1

C95400, ASTM B148

09

Nut

2

1045,ASTM A29

08

Gland

1

DI,ASTM A536 65-45-12

07

Bolt

2

1045,ASTM A29

06

Yoke

1

DI,ASTM A536 65-45-12

05

Stem

1

S.S.304,ASTM A276

04

Sealing Pad

1

EPDM,ASTM D2000

03

Connecting Part

1

C95400, ASTM B148

02

Disc

1

DI,ASTM A536 65-45-12 +EPDM,ASTM D2000

01

Body

1

DI,ASTM A536 65-45-12

NO.

Name

Qty

Material

Dimensions

3D Pictures

Advantages of APC Gate Valves

1.Wedge coated by high performance rubber through newest vulcanization technology to make sure precise dimension, good sealing and high corrosion resistance

2.Tight junction inner trim structure to assure longlife operation.

3.The bottom of gate valve adopted straight-through design, no foreigh matter store to make sure smooth flow and reliable sealing

4.Self-sealing design between the bonnect and body make the sealing more tight when pressure is higher wthin the allowable pressure range.

5. Multiple sealing structure to protect the stem under pessure during operation maintenance , no damage to the operator.

Learn More

Technical Features

*Nominal Pressure: 200PSI

*Flange Standard: ASME/ANSI B16.1 Class 125 or ASME/ANSI B16.42 Class 150

or BS EN1092-2 PN16 or GB/T9113.1

*Face to Face Standard: ASME B16.10.

*Sizes: 2",2½", 3", 4", 5”, 6", 8", 10", 12" with FM UL CUL

14", 16" with FM only

*Approvals: FM,UL, CUL, NSF/ANSI 61 & NSF/ANSI 372

*Maximum Working Pressure: 200 PSI (Maximum Testing Pressure: 400 PSI) conforms to UL 262, ULC/ORD C262-92 , FM class 1120 / 1130.

*Maximum Working Temperature:80°C / 176°F

*Coating Details:Epoxy coated interior and exterior by Electrostatic Spray or Coating upon request

*Certified lead-free by NSF/ANSI 61 & NSF / ANSI 372 is available.

Learn More

APC Industries

Mobile website

Add WeChat chat

CONTACT US

Add:No. 18 Taishan Road, Ningjin County, Shandong Province P.R.China

Mobile:+8618600252968

WeChat:cuiyuying01

E-Mail:

Customer Message